Beneath the svelte surface of the new Lexus LC 500 lies a new rear-wheel drive platform. We take a look at the constituents of this new high-tech, high-strength chassis.

The mission for the LC 500’s development team was for the car to deliver a more dynamic driving experience and character unlike that of any previous Lexus model, while maintaining the superior ride quality that has always been a performance hallmark of the brand.

The coupe is the first model to use Lexus’s new rear-wheel drive platform, part of a new corporate global architecture for luxury vehicles (GA-L). The car’s underpinnings will provide the template for Lexus’s future front-engine/rear-wheel drive vehicles.

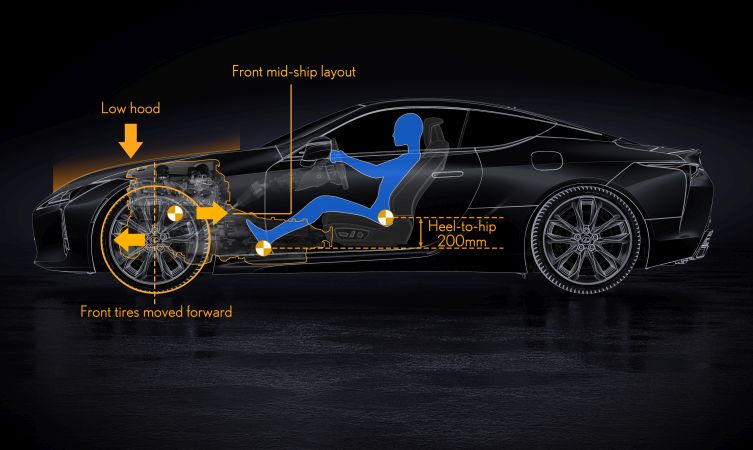

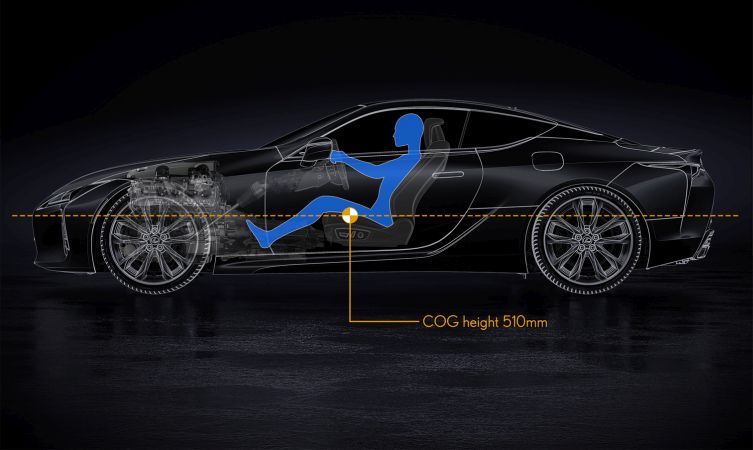

As part of their work to sharpen the car’s handling, the engineers focused on the platform’s fundamental qualities, placing most of the mass, including the engine and vehicle occupants, lower and in a more central position in the chassis, improving the centre of gravity. Internally this strategy was known as the “inertia spec”.

The driver’s hip and heel points have been set lower, the wheels have pushed out to the corners of the vehicle, with shorter overhangs, and the drivetrain mass has been located behind the front axle line to create a front-midship layout. The LC 500 uses run-flat tyres to improve packaging, reduce weight (no spare is required) and help reduce overhangs to help meet dynamic targets. The 12-volt battery has been located in the boot as part of the weight redistribution programme.

Other measures in this area include the optional carbon fibre roof, aluminium door skins mounted on a carbon fibre inner door structure and a composite boot floor. The LC 500 also represents Lexus’s most intensive use yet of high-strength steel, providing higher rigidity while reducing – and ideally positioning – vehicle mass to optimise dynamic performance. The result is a very balanced car with a near-ideal 52/48 front/rear weight distribution.

To achieve the targeted chassis performance, Lexus engineered the stiffest monocoque it has ever produced. Strategic use of lightweight, high-strength steel helps realise a high degree of torsional rigidity, with greater resistance to twisting forces than the carbon fibre-intensive LFA supercar.

The platform design maintains an even level of resistance to flexural forces and a high degree of stiffness across the vehicle’s wheelbase to help create consistent, predictable handling behaviour and sharper steering responses. Special braces in the engine compartment (part of the chassis that is particularly susceptible to twisting), the use of stiff aluminium front suspension towers and the addition of a ring structure near the rear wings all help bolster the strength of key chassis structures.

Particular attention was paid to the multilink suspension system. Double ball joints on the upper and lower control arms allow for control of the smallest movements from driver inputs and road conditions. Beyond sharing the workload, the double ball joint arrangement helps optimise suspension geometry to increase wheel control and create a more precise steering response with better initial effort. To help reduce unsprung weight and improve suspension response, all but one of the control arms are made of lightweight forged aluminium.

The Detroit show car is fitted with Michelin Sport tyres: 245/40RF21 at the front and 275/35RF21 at the rear. The combination of all the handling elements produces a world-class luxury sports coupe with razor-sharp reflexes, exceptional handling balance and rock-solid stability. Furthermore, this all-new platform will be continuously improved throughout the vehicle’s lifecycle.

Chief Engineer Sato said: “We spent more than three times the usual R&D time to pursue linear steering and to find the sweet spot for road contact feel. We also focused our efforts on suspension rigidity and enhancing geometry. Thanks to advances in product engineering, we are now at a world-class level for suspension rigidity and performance when lateral G-forces are applied.”

Learn more: Exterior design of the Lexus LC 500

Learn more: Interior design of the Lexus LC 500

Learn more: Powertrain of the Lexus LC 500

will 19 inch wheels with Michelin pa5 wrk for lc 500

Hi Robert,

Thanks for getting in touch with us and apologies for our delayed response. in this case, we can only recommend factory fitted tyres for the LC 500. If you could please provide us with the reg of your vehicle, we can check with our parts team for the exact tyres you would need.

Thanks.