As the new flagship luxury coupe of the model range, the Lexus LC delivers an outstanding showcase of talent in the fields of vehicle design, engineering and technology. But while evidence of design is broadcast through the LC’s seductive styling, other features can sometimes be hidden from view.

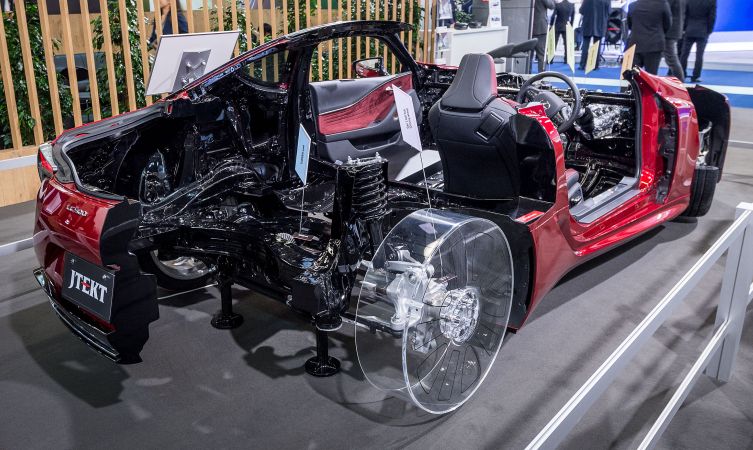

Which is probably why this unique ‘see-through’ Lexus LC 500 proved to be a show-stopping exhibit at the recent Frankfurt motor show. Produced by original equipment manufacturer JTEKT to display its high-quality bearings, steering and driveline components, the exhibit also offered a fascinating behind-the-scenes view of a number of key engineering features.

Beginning from the ground up, the wheel assembly had lost around one third of its circumference in order to expose the hub unit. However, the wheel itself is a stunning example of race-derived technology that should not be ignored.

Evidence of design is broadcast through seductive styling but other features can sometimes be hidden from view

Not only is LC the first model in its segment to be available with 21-inch alloys, but each of these wheels is carved from a single billet. This lengthy machining process retains the tight, interlocking grain structure created during the original forging process, which in turn endows the wheel with superior strength and less weight than an equivalent cast alloy – a wheel made by pouring molten metal into a cast.

Forged alloy wheels are rarely available in factory specification due to their prohibitive cost but come as standard on Sport Pack and Sport + Pack grades.

Distributing torque between the rear wheels of Sport + Pack grade models is a Torsen Type-B differential. In this image we can see its housing cut away to expose the engagement of planetary and side gears.

Engineered to be immediately sensitive to changing torque inputs, the differential continuously distributes a stabilising amount of torque across both axles in order to give the LC predictable, natural-feeling handling behaviour. Whether accelerating or decelerating, this feature allows the driver to scribe smooth arcs around bends with minimal steering correction.

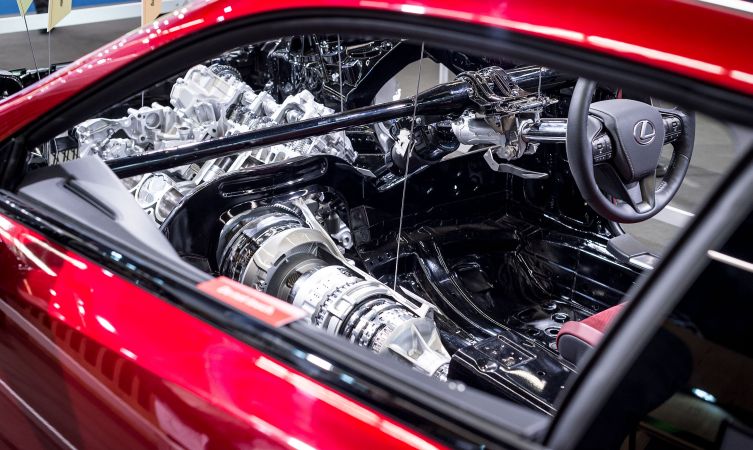

With regards to the steering, a number of important engineering features have been adopted to improve the LC’s steering feel. Communication is enhanced with a specially tuned electric power steering system, which includes variable gear ratios to reduce effort at low speeds and improve the feeling of stability at high speeds. Meanwhile, a relatively large steering shaft and tube diameter has been specified to increase rigidity, the purpose of which is to reduce the transmission of vibrations through the steering wheel.

The heart of the LC 500 is without question its 2UR-GSE engine – a naturally aspirated 5.0-litre V8 that delivers phenomenal response, spine-tingling noise, and a feeling of unending acceleration. However its headline figure of 471bhp at a heady 7,100rpm would not be possible without work put in behind the scenes by the engine’s internals.

While the V8 engine provides the tune, the new ten-speed transmission provides the beat

Peering into these all-alloy components we find lightweight yet high-strength materials deployed throughout, from the forged conrods that are contoured into an I-beam design to eliminate excess material to the titanium valves and springs that allow the engine to ‘sing’ at high revs. Thanks to electronically actuated variable timing, those same valves can be sequenced to alter the engine’s compression and expansion strokes to deliver two different combustion cycles – Otto for when power is needed and Atkinson to deliver low fuel consumption in cruising conditions.

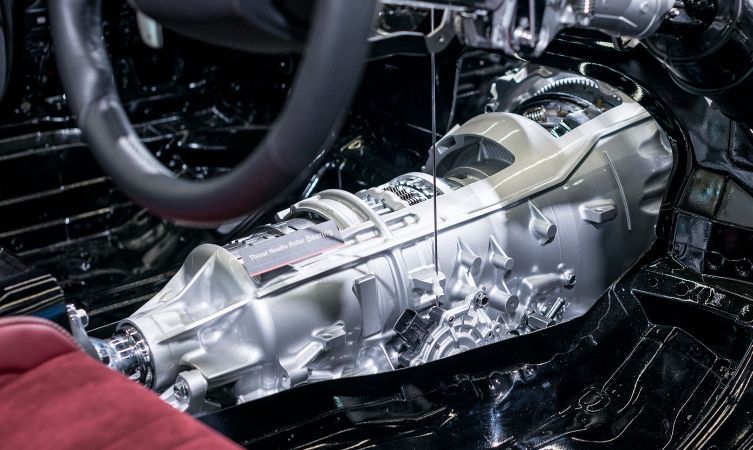

While you could say that the V8 engine provides the tune of the LC 500, the new Direct Shift-10 automatic transmission provides the beat. By closely stacking its ten gears – a world-first in a premium passenger car – the feeling of working the engine within its sweet spot is intensified.

The closely stacked gears allow the car and driver to fall into a natural rhythm

The transmission packs a range of gear ratios that is over 20% wider than the eight-speed unit installed in the RC F and GS F. Yet each of the gears from two to eight captures an even proportion of the overall range that allows the car and driver to fall into a natural rhythm. Gearchanges are also incredibly fast, giving the transmission the responsive feel of a twin-clutch gearbox in addition to the traditional smoothness and durability of a torque converter automatic.

It is incredible to confirm from this exhibition model that the physical size of this Direct Shift-10 transmission is no bigger than Lexus’s eight-speed unit. Similarly, the use of aluminium for the clutch drum, clutch hub and planetary carrier, not to mention the unseen moulded resin for the oil pan, has allowed Lexus to achieve a weight that is at least equal to the eight-speed transmission.

I have had the pleasure to get alongside 1 of these spectacular pieces of automotive art they look like they are absolutely flying even stationary, absolutely beautiful vehicles

Hi Richard,

Thank you for your kind words.