No other car in the Lexus range embodies progressive technology more demonstrably than the flagship LS model. In the first of this four-part series, we offer a glimpse of the incredible lengths Lexus went to in order to produce the finest possible automobile with the most advanced materials and technology. We start with the first-generation model launched in 1989.

History of the Lexus LS: first generation

Known internally as ‘Circle F,’ the project to develop a new flagship luxury vehicle was given the go-ahead in 1983 and was in full swing by the autumn of 1984. Over the years this project represented the work of 60 designers, 1,400 engineers split up into 24 teams, 2,300 technicians and over 200 support workers.

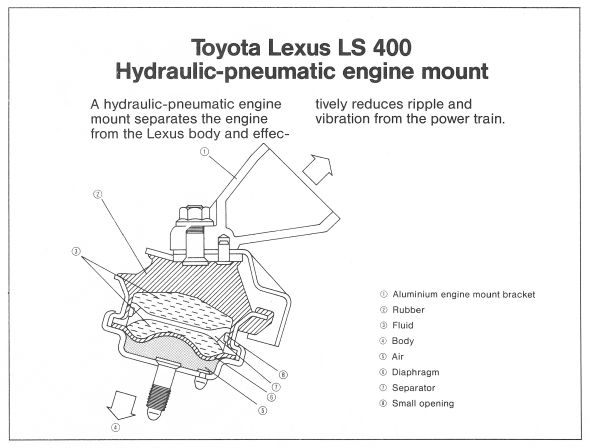

At the heart of the first-generation Lexus LS was a 4.0-litre V8 powerplant that represented the pinnacle of the parent company’s engine-building skills. After testing a total of 973 prototypes, the new 1UZ-FE engine featured an aluminium block with cast iron cylinder liners for immense strength, and the crankshaft ran on five bearings for maximum support. Four camshafts were employed in order to utilise four valves per cylinder, while lightweight aluminium cam followers were used to reduce inertia in the valvetrain – a world first. Smooth running was ensured by reducing the machining tolerances of all moving parts by up to 50%, and the engine itself was suspended on special hydraulic-pneumatic mounts.

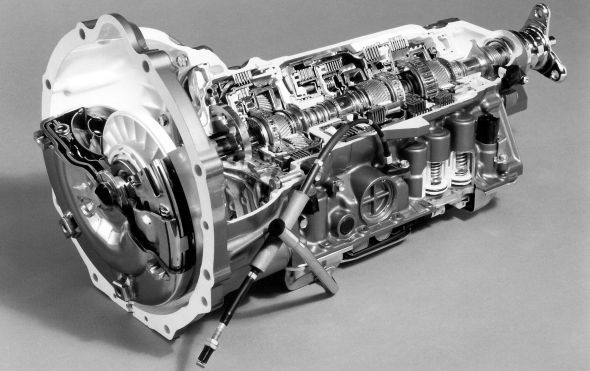

Allied to this was a new computer-controlled automatic gearbox that featured its own ECU. It was designed to ‘talk’ to the engine’s ECU and tell it when to momentarily retard the ignition timing. This split-second reduction in torque reduced the load on the transmission and allowed the gearbox to make its changes with improved smoothness. An additional layer of hydraulic control allowed the clutches to engage with just enough pressure depending on the level of accelerative force running through the transmission.

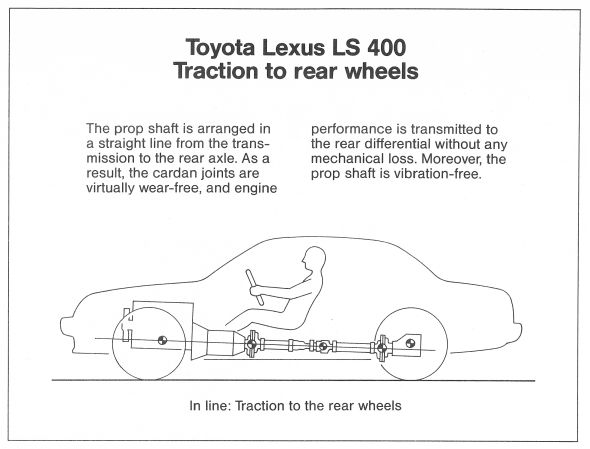

A similar level of effort was employed throughout the rest of the driveline and differential. The engine was tilted back slightly to allow the two-piece propshaft (each section of which was tested and corrected for primary and secondary imbalance) to lie in a perfectly straight line and therefore minimise the chances of vibration.

Meanwhile, a new differential was composed with more gear teeth than normal, up to 30% less slack between gears, and with all internal components produced with 33% less tolerance for dimensional inequalities. But more than this, every movement between the differential’s ring and pinion gears was filmed and visually examined for acceptable tooth-to-tooth contact.

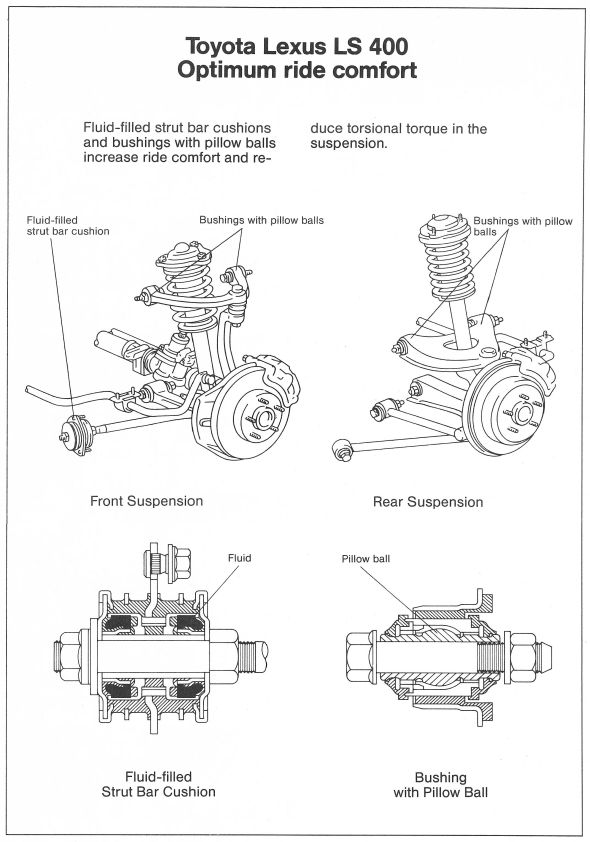

The chassis work was incredibly involved too. Complex double wishbones with high-castor geometry and low kingpin offset were employed on all four corners for optimum stability and reduced steering effort. This was combined with optional computer-controlled air suspension that adjusted its responses and ride height depending on speed, load and terrain. The level of power steering assistance was also governed by vehicle speed.

All components used in the creation of the LS were destruction-tested and subjected to an accelerated ageing process as part of a special durability programme. To ensure the greatest longevity, most body components were fabricated from corrosion-resistant materials such as stainless steel and high-quality steel sheet.

The bodyshell itself was stiffer than any other contemporary luxury car, with welds 1.5 times stronger than those in a normal vehicle. Notably, LS was the first car in the industry to feature laser welding techniques, which allowed five sheets of different gauge steel to be welded together and pressed as a single entity. Using this process, unsightly weld lines normally visible within the door shuts of traditionally welded panels are impossible to find on the first-generation Lexus LS.

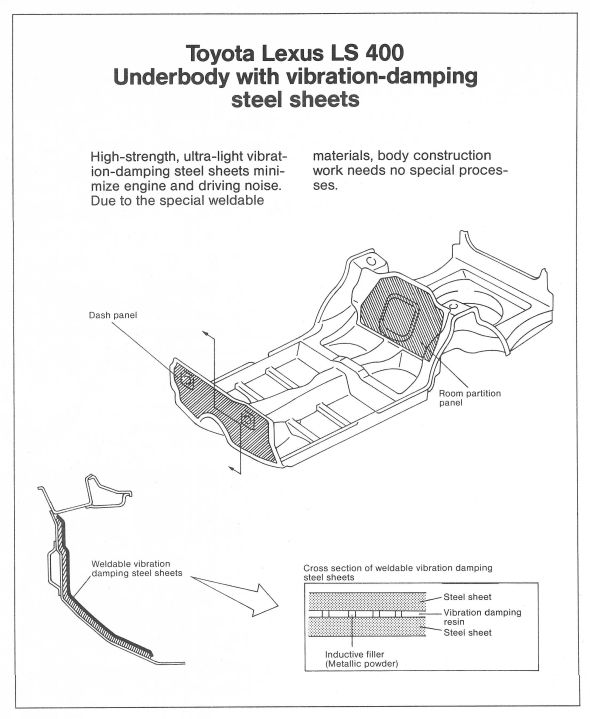

Another world-first technology devised for the LS was in being the ability to weld sound-insulating sandwich panels into the double-skinned front and rear bulkheads. Cleverly, the resin sheet used as the filling in these sandwich panels contained a metallic powder that conducted enough electricity to allow the penetration of spot welds.

Externally, the level of attention to detail was borderline obsessive. Panel gaps were incredibly tight and computer-measured for conformity, yet the distance between the bonnet and front wings, and boot lid and rear quarter panels, was designed not to be parallel. This was so that if the car was viewed directly from the front or rear, the perspective of a slightly tapered gap actually appears more parallel than one that is perfectly straight.

Then there was the way the angle of the windscreen wipers was designed to change as vehicle speed increased, and the fact that the indicators as well as bumpers were designed to withstand 5.0mph impacts. Finally, the door mirrors produced ultrasonic waves as well as featuring an internal heating element to clear moisture.

Four layers of weatherproof strips were inserted into each door frame to ensure noise and dirt were shielded from those inside, while beams were inserted into the doors to ensure occupants were protected in the event of a side impact.

The inside of the LS was purposed to provide a typically Japanese environment, balanced somewhere between the austerity and opulence found in German and American cars of the time. Two years were spent simply deciding on the right tanning methods, grains, textures and feel, while the wood was finished by the piano-makers at Yamaha.

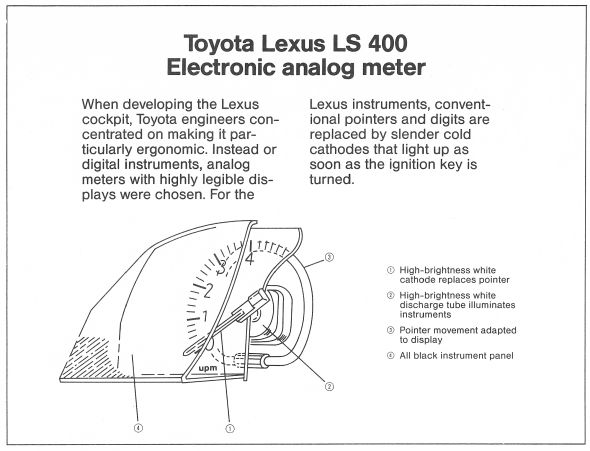

The LS dashboard featured new Optitron gauges that glowed with a three-dimensional effect and delivered less strain on the eyes. Also in front of the driver was the world’s first tilt-and-telescopic steering wheel equipped with an airbag; and to underline this fact there was a facility for the wheel to move out of the way once the ignition key had been removed.

In every aspect of the new LS’s development, quality and safety were the watchwords. One hundred prototypes were crash-tested during the design of the car’s crash-absorbing body structure. During production itself, each car went through 300 more inspection procedures than any other Toyota, a process that contributed to Lexus’s new Tahara Plant receiving recognition as the most fault-free production facility in the world.

Considering the lengths Lexus went to in its quest to make the world’s finest luxury car, many might have wondered whether it was possible to improve on the first-generation LS. Why not click through to the second instalment to see how the introduction of new technology allowed the engineers to accomplish the seemingly impossible?

All information was correct at the time of publishing.

THE LS400 THE VERY BEST EVER CAR ON THE PLANET , I KNOW I HAVE OWNED AT LEAST 9 !

I have had my 1989 as 400 for 15 years and it is the best car I have driven in 54 years of driven